MS Puddle Flange Fabrication – Custom Sizes, Drawing & QA

MS Puddle Flange Fabrication – Custom Sizes, Drawing & QA

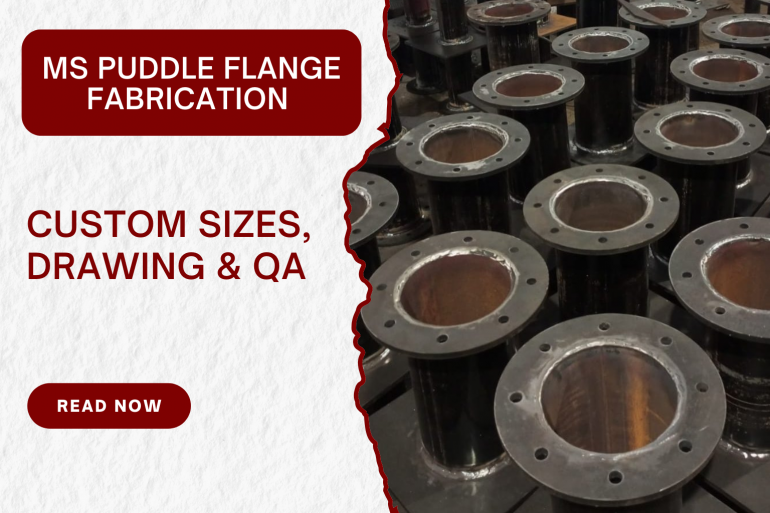

MS puddle flange fabrication involves custom manufacturing of steel flanges that are welded to pipes for waterproofing purposes in RCC structures. These flanges prevent water leakage and are embedded directly in concrete walls, tanks, or slabs. For specialized construction jobs, puddle flanges are fabricated as per client-specific OD, thickness, and pipe bore sizes.

What Is Custom MS Puddle Flange Fabrication?

Unlike standard flanges, custom puddle flanges are fabricated based on project specifications and may vary in material grade, thickness, diameter, or coating. These are essential in government tenders, builder BOQs, and drainage works that need precise sealing.

Drawing Details Required for Fabrication

- Pipe Bore (NB or OD)

- Outer Diameter (OD of flange)

- Thickness (mm)

- Material – MS, GI, or Epoxy Coated

- Welding Spec – Seam type / continuous / spot weld

- Coating Requirements (bitumen, epoxy, or galvanized)

Drawing Formats Accepted

- PDF Fabrication Drawing

- AutoCAD DWG File

- Sketch with Dimensional Notes

- Excel BOQ Reference (with specs)

Fabrication Process Overview

- Receive BOQ / Drawing from client

- Cut MS plate or ring to OD and ID

- Machine to desired thickness

- Weld to pipe / sleeve as required

- Apply coating (optional)

- Final QA check before dispatch

Quality Checks (QA & QC)

- Visual Inspection – Flatness, roundness, and weld uniformity

- Thickness Verification – With vernier/digital calipers

- Weld Strength Test – On request (penetration or spot)

- Coating Adherence – Scratch & adhesion check

- Marking & Batch Numbering

Popular Sizes in Custom Puddle Flange Orders

| Pipe Size (NB) | Flange OD (mm) | Thickness (mm) | Coating |

|---|---|---|---|

| 100 NB | 220 | 8 | Epoxy / GI |

| 150 NB | 285 | 10 | MS Painted |

| 200 NB | 340 | 12 | Epoxy |

| 250 NB | 395 | 12 | Bitumen |

| 300 NB | 445 | 15 | GI |

Documents Provided

- Test Certificate for MS plate

- Inspection Report with flange count

- Drawing approval sheet

- Weight calculation sheet (on request)

Order MS Puddle Flange with Fabrication

Related Articles

- MS Puddle Flange Price List PDF

- Puddle Flange Size & Weight Chart

- MS Puddle Flange – Dimensions & Usage

FAQ – MS Puddle Flange Fabrication

Q1. Can I order a single puddle flange with drawing?

Yes, single unit orders with custom sizes are accepted for urgent civil works.

Q2. What is the lead time for fabrication?

Standard orders: 2–4 days. Complex drawings or coating: up to 7 days.

Q3. Is QA report included in price?

Yes, QA/QC checks and visual inspection report is included. Material TC available on request.

Q4. Which coating is best for RCC wall?

Epoxy or bitumen coating is most commonly used for waterproofing.

Comments : 0